AI Is Real. Wall Street Is Confused. Here's What Technology Leaders Need to Do Now.

I don't usually write posts like this. Azure411 is where I talk about Azure, infrastructure, migration, and what energy leaders need to do next with cloud. But what's happening right now in AI is bigger than any single platform. And if you lead people, manage budgets, or make technology decisions in the energy sector, you need to hear this.

A few days ago, Matt Shumer, the CEO of OthersideAI who's spent six years building AI products, published a piece called "Something Big Is Happening." It went viral for good reason. It's one of the most honest, clear-eyed things I've read about where AI actually is right now. Not where the vendors say it's going. Where it is. I'd strongly encourage you to read it in full.

What I want to do here is different. Shumer wrote for his friends and family, for non-tech people trying to understand what's coming. I want to take that same urgency, add the Wall Street data that proves the scale of what's happening, and then go somewhere Shumer didn't: into the specific, concrete ways AI is about to transform the energy industry. Not vague promises. Real scenarios grounded in real data, for the energy IT leaders, grid operators, utility CIOs, and operations teams I work with every day.

Some of the advice in this post is inspired by Shumer's recommendations, adapted for energy industry. Where I've built on his ideas, I'll say so. But the Wall Street analysis, the energy use cases, and the vision for where this takes our grid? That's mine.

Because this isn't just a tech industry story anymore. It's ours.

Wall Street Is Confused. That's How You Know This Is Real.

Before I get into the practical advice, I need to talk about something that's been bugging me. Because if you've been watching the markets, you might think AI is in trouble. And that misread could cost you years.

Here's what happened: Microsoft beat earnings, $81.3 billion in revenue, 17% growth, crushed expectations on both top and bottom line. Microsoft Cloud crossed $50 billion in a single quarter. Their commercial backlog more than doubled to $625 billion. By every operational measure, this was a monster quarter.

The stock dropped 14%.

Not because the business is failing. Because Wall Street looked at the $37.5 billion Microsoft spent on AI infrastructure in a single quarter, on pace for roughly $145 billion this fiscal year, and panicked about when that spending turns into proportional returns. Azure growth came in at 39%, down one point from the prior quarter. Demand still exceeds supply. They're capacity-constrained through at least mid-2026. And investors sold because 39% growth wasn't fast enough relative to the money going out the door.

The same story played out across the board. Alphabet announced 2026 capex guidance of $175 to $185 billion, roughly double 2025, and the stock dropped. Meta guided $115 to $135 billion in spending. Amazon fell 8% after raising its capex forecast. All four hyperscalers are projected to spend roughly $650 billion combined on AI infrastructure this year. Bloomberg called it a spending boom without parallel this century.

And then, in the same two weeks, the software sector lost nearly $1 trillion in market value. Not because software is dying. Because investors suddenly realized that the AI these companies are building might disrupt existing software business models. Salesforce dropped 26% year-to-date. ServiceNow fell 28%. Intuit cratered over 34%. The S&P Software & Services index had its worst monthly decline since October 2008. A JPMorgan analyst said the sector is being "sentenced before trial."

Read that again. Wall Street is simultaneously punishing the companies building AI for spending too much, AND punishing the companies that AI might disrupt for not adapting fast enough. They're scared of the investment AND scared of what the investment produces.

That's not rational analysis. That's the market trying to price in something it has never seen before. And it tells you something critically important: Wall Street knows this is real. It just doesn't know how to value it yet.

Let me put the spending in energy terms so it lands: the entire U.S. electric utility industry spends roughly $160 billion a year on capital expenditures, generation, transmission, distribution, everything. Four tech companies are spending four times that on AI in a single year. CreditSights estimates roughly 75% of that, around $450 billion, goes directly to AI infrastructure. These companies have seen the demand. They've booked the contracts. Microsoft alone has $625 billion in commercial backlog. That's not hope. That's signed business that Wall Street is too confused to properly value.

The RBC Capital Markets analyst covering Microsoft called the selloff a buying opportunity and said the market is being "pretty irrational." One European fund that has beaten 99% of its peers over three years responded to the crash by buying more Microsoft.

Here's what I want energy leaders to take away from this: Don't look at the stock prices and conclude AI is faltering. Look at the spending. Look at the backlog. Look at the fact that Microsoft is capacity-constrained, they literally cannot build data centers fast enough to meet customer demand. The biggest companies on earth are committing more concentrated capital than at any point in modern economic history. They're not doing this because their investors want them to. They're doing it because their customers are demanding it.

The companies betting real money, hundreds of billions of it, have already seen what's coming. Wall Street will figure out how to price it eventually. But the companies that actually use AI to transform their operations aren't waiting for investors to catch up.

And neither should you.

What Actually Changed

Here's what most people outside of tech don't fully grasp yet. And I'll be honest, I'm inside the Microsoft ecosystem every day, and even I've been caught off guard by the pace.

In early February 2026, two major AI labs released new models on the same day. OpenAI dropped GPT-5.3 Codex. Anthropic released Claude Opus 4.6. And something shifted.

These aren't incremental upgrades. As Shumer described in his post, software engineers are reporting that they describe what they want, walk away, and come back to finished work. Not drafts. Not rough outlines. Finished product. The AI tests its own work, iterates, and refines before handing it back. Shumer put it bluntly: "I am no longer needed for the actual technical work of my job."

Now, I know what you're thinking. That's a software guy. My world is substations and SCADA systems and NERC CIP compliance. That's different.

It is different. Today. But here's the key insight Shumer explained that matters for every industry: the AI labs focused on code first on purpose. Making AI great at writing code was a strategic choice because better code builds better AI, which writes better code, which builds better AI. It's a self-reinforcing loop. Now that they've cracked it, they're aiming that capability at everything else. Law, finance, medicine, analysis, operations, planning.

Energy is not immune. No field is.

What This Means for Energy Leaders

Let me bring this home to the conversations I have every week with CIOs, VPs of IT, and operations leaders at utilities and energy producers.

Your planning teams build load forecasts, model seasonal demand, run scenario analysis for winter peaks and summer storms. AI can do this. Not someday. The models available right now can analyze massive datasets, build models, find patterns, and deliver insights that would take your analysts days, in minutes.

Your compliance teams navigate NERC CIP, DOE 10 CFR Part 810, state PUC requirements, FERC filings. AI can read regulatory documents, cross-reference your policies, draft gap analyses, and flag risks. It's not replacing your compliance officer. But it's about to make a team of three do the work of ten.

Your field operations generate mountains of inspection reports, maintenance logs, asset data. AI can synthesize that information, spot trends your teams would miss, and prioritize work orders based on actual risk rather than calendar schedules.

Your IT organizations are already stretched thin, managing aging on-prem systems alongside cloud migrations, trying to keep the lights on while also innovating. AI is about to become the force multiplier that changes that math entirely.

But those are the near-term wins. The obvious ones. Let me paint you a picture of where this goes, because this is the part I think about late at night, and it's the part that genuinely excites me about what AI means for the people in our industry.

No More Knocking on Doors at 3 AM

I need to talk about something that doesn't show up in vendor slide decks.

Every year, roughly 26 linemen die on the job in the United States. The fatality rate for electrical power line installers is about 20 per 100,000 workers, making it one of the ten most dangerous jobs in the country. Electrocution is the leading killer. Falls from utility poles and aerial lifts account for another 21%. And those are just the deaths. For every lineman killed, approximately 20 more suffer serious non-fatal injuries: electrical burns, lost limbs, traumatic falls.

These aren't statistics. These are people. They're the crews who drive into a Category 4 hurricane while everyone else drives out. They're the ones who climb a utility pole at 2 AM in an ice storm because your hospital needs power. They work 16-hour shifts in conditions that would stop most people cold, and they do it because they believe in the mission of keeping the lights on. A lineman in Indiana named Erick Trice described his hurricane response schedule: start at 6 AM, work for 16 hours, collapse in a hotel, alarm goes off, do it again. His wife and kids wait. His colleagues wait. And sometimes, the call that comes home is the worst one imaginable.

I've sat in enough utility offices to know: every leader in this industry carries the weight of knowing that sending crews into the field means accepting risk to human life. It's the unspoken cost of keeping the grid running.

AI and robotics are about to change that equation.

Boston Dynamics unveiled the production version of Atlas, their electric humanoid robot, at CES in January 2026. All 2026 deployments are already fully committed. The CEO, Robert Playter, said it bluntly: "We would like things that could be stronger than us or tolerate more heat than us or definitely go into a dangerous place where we shouldn't be going." These robots are being designed to operate in power plants, construction sites, and unstructured environments, exactly the kind of places where we lose people.

And it's not just humanoids. Duke Energy's Oconee Nuclear Station already uses Boston Dynamics' Spot robot for inspections inside containment areas. Ontario Power Generation uses them too. In Finland, an autonomous quadruped robot patrols the Onkalo spent nuclear fuel repository, 400 meters underground, in a network of tunnels, performing radiation monitoring and visual inspections so humans don't have to. At Fukushima, robotic systems swim inside reactor vessels to inspect welds in environments where a human would receive a lethal radiation dose in minutes.

Now combine these physical robots with the AI that just leaped forward this month. Think about what happens when you pair an Atlas humanoid, one that can crouch, lift, climb, and manipulate tools, with an AI brain that has judgment, that can assess a situation, make a decision, and adapt in real time.

Imagine this: A derecho tears across your service territory at 90 mph. Instead of sending a two-person crew up a damaged pole in 40-degree rain in the dark, you deploy a humanoid robot that can climb the structure, assess the damage with thermal and visual sensors, and either make the repair or report back exactly what's needed, all while your linemen monitor from a warm truck with a tablet. The robot doesn't get electrocuted. It doesn't fall. It doesn't get tired at hour fourteen. And if it does get hit with a fault current, you replace a machine. You don't knock on someone's door at 3 AM to deliver the worst news of their life.

We're not ten years from this. Boston Dynamics' chief strategy officer said general-purpose humanoids doing dangerous jobs will be reality by the end of this decade. The AI models powering them are doubling in capability every four to seven months. The physical platforms are shipping this year.

For nuclear operators, and several of my customers are nuclear, the implications are even more immediate. Refueling outages, containment inspections, spent fuel handling, radiation surveys in high-dose areas: these are tasks where every minute of human exposure carries risk, and every task performed robotically is a dose avoided. AI-driven autonomous robots that can navigate reactor buildings, read analog gauges, detect anomalies, and report findings without a single human entering a radiation area? That's not science fiction. Elements of that are deployed today. The full vision is closer than most people in the industry realize.

The day is coming, and it's coming fast, when the most dangerous work in the energy sector is performed by machines that don't leave families behind.

That's not a threat to our workforce. That's the promise we owe them.

The Grid That Thinks for Itself

Here's another thing that keeps me up at night, but in a good way.

Eighty percent of major U.S. power outages since 2000 have been caused by weather events. The Department of Energy estimates those outages cost the economy over $150 billion every year. We've been fighting this problem the same way for decades: build stronger poles, trim more trees, stage more crews before the storm, and respond as fast as we can after things break. It's heroic work. But it's fundamentally reactive. We're still waiting for things to break and then racing to fix them.

AI is about to flip that model on its head.

Eversource Energy partnered with EY to build an AI-powered outage prediction system that integrates weather patterns, vegetation data, SCADA telemetry, GIS mapping, and historical outage records. The result? They avoided 40,000 customer outages in just two months. Not faster restoration. Outages that never happened in the first place. In Texas, a utility used machine learning models to reduce storm-induced outages by 72%. ERCOT is actively developing ML-powered decision support for real-time grid operations. Hydro-Québec put deep neural networks into production for load forecasting, and during a 2024 heatwave, the AI model correctly predicted an unusual demand pattern that two legacy models completely missed, a 1,500 MW forecasting error avoided because the machine saw what experienced operators didn't.

And that's with today's AI. The stuff that the models released this month already make look primitive.

Now project forward. Not decades. Years.

Imagine an AI that ingests every data point your utility generates, SCADA, AMI smart meter readings, weather radar and satellite imagery, LiDAR vegetation surveys, asset age and maintenance history, soil moisture levels, transformer loading curves, historical outage data going back decades, and doesn't just predict that a storm will cause outages. It tells you exactly which circuits will fail, in what order, and why.

It says: "Feeder 4412 out of Elm Street substation will experience a tree-contact fault on span 47 approximately 3 hours into the storm. The red oak at coordinates 41.2847, -83.1152 has grown 14 inches since last survey and will contact the phase-A conductor at sustained winds above 55 mph. If you trim that one tree tomorrow, you prevent 2,300 customer outages and an estimated 8-hour restoration."

One tree. Identified by AI. Trimmed before the storm. 2,300 families that never lose power and never know how close they came.

That's not a fantasy. Every piece of that data exists today in most utilities. What's been missing is the intelligence to connect it all, weigh the variables, and produce an actionable answer. That intelligence just arrived.

The $1 Million Question AI Can Finally Answer

And then there's the capital planning revolution, the one that could fundamentally reshape how we build and harden the grid.

Here's a question every utility executive has faced: Should we bury this section of line?

The data has always been clear on the broad strokes. Underground circuits experience roughly 75-80% fewer outages than overhead lines. A North Carolina reliability study confirmed that underground systems have 50% fewer outages, and Virginia and Long Island data showed underground circuits experience only 20-25% of the outages that overhead circuits see. Stanford researchers found that burying just an additional 25% of overhead lines could have reduced outage duration by nearly 40% during a major nor'easter. The upside is enormous.

But the cost is staggering. Underground distribution costs five to ten times more than overhead, often $1 million or more per mile versus $100,000 to $200,000 for overhead. And the tradeoffs are real: underground faults take three to four times longer to locate and repair, cable life can be shorter due to moisture and corrosion, and some terrain simply won't cooperate.

So the question has always been: which miles? Which specific segments of your system would deliver the greatest reliability improvement per dollar invested? That's a question no human planning team could comprehensively answer because the variables are too numerous, too interconnected, and too dynamic. You'd need to weigh storm frequency by geography, vegetation density and growth rates along each span, soil conditions and water tables, customer density and criticality (is this feeder serving a hospital or a strip mall?), historical outage patterns by cause, conductor age and condition, flood plain exposure, wildfire risk, future load growth from EV adoption and data centers, and a hundred other factors.

That's exactly the kind of multidimensional optimization problem that AI was born to solve.

Imagine this: Your AI ingests every piece of your system data, GIS, asset management, outage management, weather history, vegetation surveys, customer data, soil surveys, terrain models, and financial models. You ask it a simple question: "If I have $50 million for grid hardening this year, where does every dollar create the most reliability improvement?"

And it comes back with something like: "Bury the 12.3-mile segment of Feeder 2209 between Oak Ridge substation and the Lakeview tap. This corridor has experienced 847 weather-related outages in the past decade, 78% from tree contacts and ice loading. Soil conditions are favorable, sandy loam, low water table, no bedrock above 8 feet. Undergrounding this segment eliminates an estimated 82% of those outages, improves SAIDI for 11,400 customers by 43 minutes annually, and pays back in avoided storm restoration costs within 9 years. Additionally, hardening the overhead section of Feeder 3318 from Span 12 to Span 31 with composite poles and covered conductor achieves 61% outage reduction at one-third the cost of undergrounding, given the granite substrata in that corridor."

Not a general recommendation. A specific, engineering-grade capital plan with financial justification, prioritized by impact, tailored to the physical realities of your territory. The kind of analysis that would take a planning team months to develop, delivered in hours, updated dynamically as conditions change, and refined every year as the model learns from actual outcomes.

This isn't just about burying lines. It's about every capital decision you make. Where to deploy distributed energy storage for resilience. Which substations to upgrade first. Where to invest in automated switching and reclosers versus physical hardening. How to stage mobile transformers before hurricane season. Where your next major generation source should connect based on grid topology and expected load growth from new data centers in your territory.

AI turns grid planning from an art practiced by experienced engineers working with incomplete data into a science operating on all the data at once. Your engineers don't go away, they become dramatically more effective because they're working with recommendations that account for factors no human could hold in their head simultaneously.

The Storm That No One Feels

Let me tie all of this together with a vision that I think is within reach in the next five to seven years. Not because I'm an optimist. Because the math on AI capability doubling says so.

Picture the next major winter storm hitting your territory.

Before the storm arrives, your AI has already run 10,000 simulations based on the forecast models. It knows which circuits are most vulnerable, which trees are most likely to contact lines, and which equipment is running closest to failure thresholds. It has pre-positioned repair robots and autonomous drones at strategic locations across your service territory. It has already adjusted the grid topology, opening and closing automated switches to create smaller, more resilient segments that can be isolated and restored independently.

During the storm, sensors across your system feed real-time data to the AI. A transformer at a critical substation starts showing thermal signatures that indicate imminent failure. The AI reroutes load to adjacent feeders before the transformer trips, and nobody loses power. A tree falls on a distribution line in a rural section. The AI isolates the faulted segment in milliseconds, restores power to 90% of affected customers through automated switching within seconds, and dispatches an autonomous robot crew to clear the tree and repair the line, all before a human operator has finished reading the first alarm.

After the storm, your customers check their phones. Most of them don't even know there was a major event. The ones who did lose power were restored in minutes, not hours or days. Your linemen, the ones who used to spend 16-hour shifts in freezing rain, monitored the operation from a warm control center, intervening only for the handful of situations that required human judgment or regulatory sign-off.

And here's the thing that gives me chills: no one died. No lineman was electrocuted on a pole in the dark. No bucket truck slid off an icy road. No family got that knock on the door.

Is that tomorrow? No. But is it a decade away? I don't think so. Every component I just described either exists today or is under active development. AI-powered outage prediction is deployed right now. Automated grid switching exists right now. Robotic inspection platforms are in use at nuclear plants and substations right now. Humanoid robots capable of working in dangerous environments are shipping this year.

What's been missing is the connective intelligence, the AI brain that orchestrates all of it together. That brain just showed up.

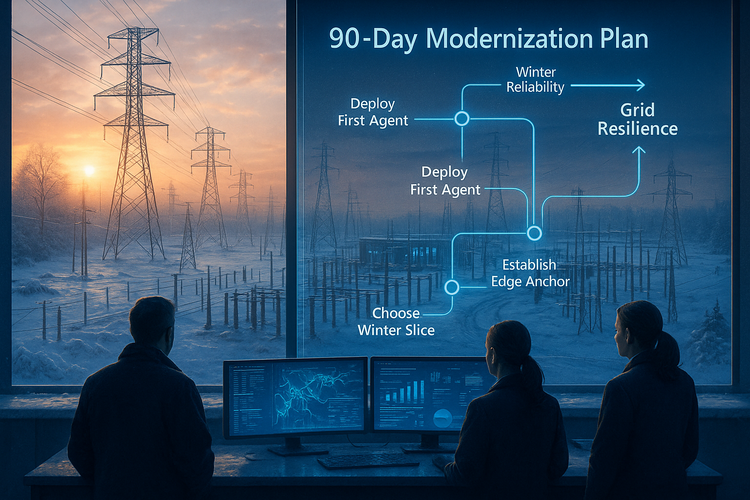

What You Should Do Right Now

I'm going to give you the same advice I'd give if we were sitting across from each other in a customer meeting. Straight talk, no hedging. Some of what follows is inspired by Shumer's practical recommendations, which I think are excellent. I've adapted them here for energy and technology leaders specifically, and added several that are unique to our industry.

1. Get your hands on the current models. Today. Not next quarter.

If you haven't used AI since 2023 or early 2024, what exists now would be unrecognizable to you. For energy and enterprise environments, I'd point you straight to Microsoft 365 Copilot. It's backed by frontier models from both OpenAI and Anthropic, but what sets it apart is that it's grounded in your own data, your SharePoint documents, your Outlook emails, your Teams conversations, your Excel workbooks. That grounding is what turns a general-purpose AI into something that actually understands your organization's context, your outage history, your vendor contracts, your compliance documentation. And critically, make sure you're selecting the best available model in the settings, not the default. The default is often a faster but far less capable version.

But don't just ask it trivia questions. That's where most people stall out. Instead, throw your actual work at it. Give it a raw export from your outage management system and ask it to identify the top ten chronic feeders driving your SAIDI. Paste in a NERC CIP evidence document and ask it to find gaps. Feed it three years of transformer oil analysis data and ask what patterns it sees. Upload a vendor RFP response and ask it to score against your evaluation criteria. The people gaining an edge right now aren't experimenting casually. They're systematically testing these tools against their hardest, most time-consuming problems.

2. This is likely the most consequential year of your career for positioning. Act like it.

Right now, the vast majority of energy companies are still in wait-and-see mode on AI. That creates a window. The leader who walks into a planning meeting and says "I used AI to run 200 load growth scenarios overnight instead of the three our team usually produces in a week" is going to change the conversation. Not eventually. Immediately.

Learn these tools deeply. Build competency on your team. Show your leadership what's possible with live demonstrations, not slide decks. If you move early enough, you become the person your organization turns to when the urgency finally hits everyone else.

That window is temporary. Once AI adoption in energy accelerates, and it will, the advantage shifts from "who adopted first" to "who's been practicing longest."

3. Combine your domain expertise with these tools. That's the real competitive advantage.

As Shumer points out, the people who struggle most with this transition will be the ones who refuse to engage, who dismiss AI as a fad or feel that using it diminishes their experience. He's right. But I'd add something specific to energy: your deep domain knowledge is what makes AI dangerous in the best sense.

AI doesn't know that your ISO requires a specific ramp rate for regulation reserves. It doesn't know that Feeder 2209 floods every March. It doesn't know that your nuclear plant's tech specs require a different voltage setpoint than what the standard model assumes. You know those things. And when you combine decades of that operational knowledge with AI's ability to process and optimize across thousands of variables simultaneously, you get something neither humans nor AI can achieve alone.

NERC CIP, nuclear licensing, FERC oversight, state PUC requirements: these regulatory frameworks create institutional inertia that will slow AI adoption in energy compared to less regulated industries. As Shumer notes, that kind of regulatory complexity buys time. But time is only valuable if you use it to build capability, not to avoid the conversation.

4. Build organizational resilience for what's coming.

If you believe even partially that AI will significantly change how energy companies operate in the next three to five years, then you need to prepare your teams and your budgets now. Cross-train your people. Identify which roles are primarily analytical or administrative and start thinking about how those roles evolve when AI handles 80% of the data processing. Create budget room for AI experimentation, not massive transformation programs, but practical pilots that compound learning over time.

For capital planning teams: start building the data foundation now. AI is only as good as the data it can access. If your GIS, outage management, asset management, and SCADA systems are siloed, the AI revolution passes you by. The single highest-ROI project many utilities can do right now is getting their operational data integrated and accessible.

5. Rethink workforce development for an AI-augmented future.

Shumer makes a compelling case that the standard career playbook, get a professional degree and land a stable knowledge-work job, points directly at the roles most exposed to AI disruption. I think he's right, and I'd extend that to energy specifically.

For your current teams, stop thinking of AI training as a one-time workshop. Build the habit of continuous experimentation. The specific tools will change every six months. What matters is building comfort with the pace of change itself. Rotate team members through AI pilot projects. Celebrate the person who finds a new use case, not just the person who delivers on the traditional KPI.

For the next generation entering the energy workforce: technical knowledge still matters enormously, but the ability to work with AI tools, to know what questions to ask and how to validate the answers, will separate the top performers from everyone else.

6. Recognize that the projects you couldn't justify just became possible.

This is the part that excites me most, and it's the flip side of the disruption story. AI is also the most powerful equalizer I've seen in my career for getting things done with limited resources.

That proof-of-concept for predictive maintenance your team pitched three years ago but couldn't get funded because you didn't have the data science headcount? Try building it with AI. That customer-facing outage map your distribution group has wanted forever? Describe the requirements to Copilot and see what comes back. That integration between your SAP PM module and your GIS system that was always "too complex" for the available budget? The complexity calculus just changed dramatically.

Energy IT teams have been resource-constrained for as long as I've been in this business. AI doesn't eliminate the need for skilled people. But it dramatically amplifies what a small team can accomplish. The utility that figures this out first gains a compounding advantage that will be very difficult for competitors to close.

The Bottom Line

I started this post with a Wall Street paradox: investors are simultaneously terrified of how much money is going into AI and terrified of what AI will do to existing businesses. They're right to be scared on both counts. But they're wrong to think the answer is to sit on the sidelines.

I want to end with a different number.

Zero.

That's the number of linemen I want to see die on the job. The number of families I want to see devastated by a preventable tragedy on a utility pole in the dark. The number of customers I want to see go without power for days because we couldn't predict what a storm would do to our grid. The number of capital planning decisions I want to see made on gut instinct when the data existed to make them with precision.

We're not going to get to zero overnight. But for the first time in my career, I can see the path.

AI gives us the intelligence to predict failures before they happen. Robotics gives us the ability to send machines into danger instead of people. Together, they give us a shot at a grid that approaches the reliability our customers deserve, one that thinks ahead, heals itself, and protects the people who keep it running.

Wall Street is confused, punishing builders and incumbents alike. The AI labs aren't confused at all. They know exactly what they've built. And the people at the top of every industry who are paying close attention, they know too. I see an industry that has always asked its people to accept extraordinary risk in service of keeping the lights on, and I see the technology that finally allows us to stop asking.

The only question is whether you see it early enough to act on it.

Shumer's advice to his readers was to commit to one hour a day experimenting with AI. I'll adapt that for energy leaders: commit to one hour a day, but make it count by using your real operational data and your real business problems. Don't read about AI. Use it. Every day, give it a harder problem than yesterday. If you do this for the next six months, you'll understand what's coming better than 99% of the leaders in our industry.

The energy sector has always been built on reliability, long planning horizons, and careful risk management. Those instincts serve you well. But right now, the biggest risk isn't moving too fast.

It's standing still.

Matt Shumer's original post, "Something Big Is Happening," is the best thing I've read this year on where AI actually stands. If you haven't read it yet, start there. Then come back here for what it means for energy. And if this post resonated with you, share it with someone on your leadership team who should be thinking about this. The people who hear it first have the biggest advantage.